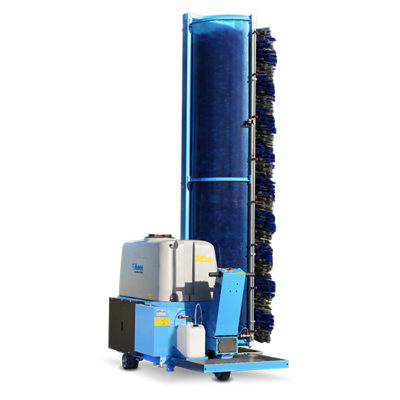

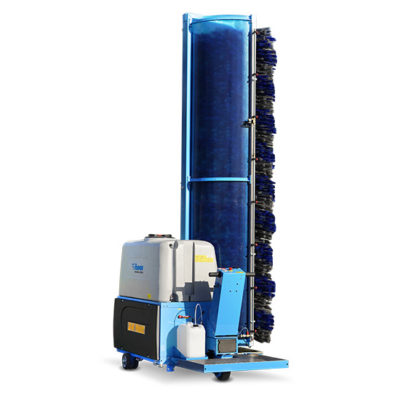

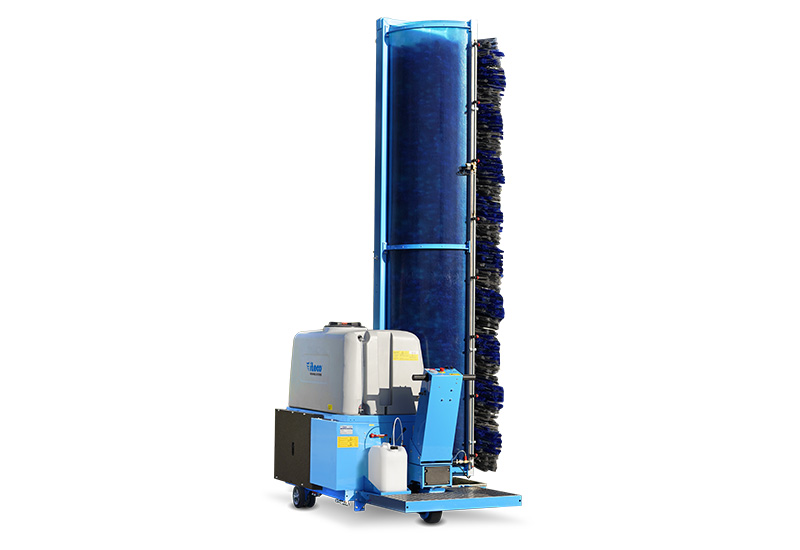

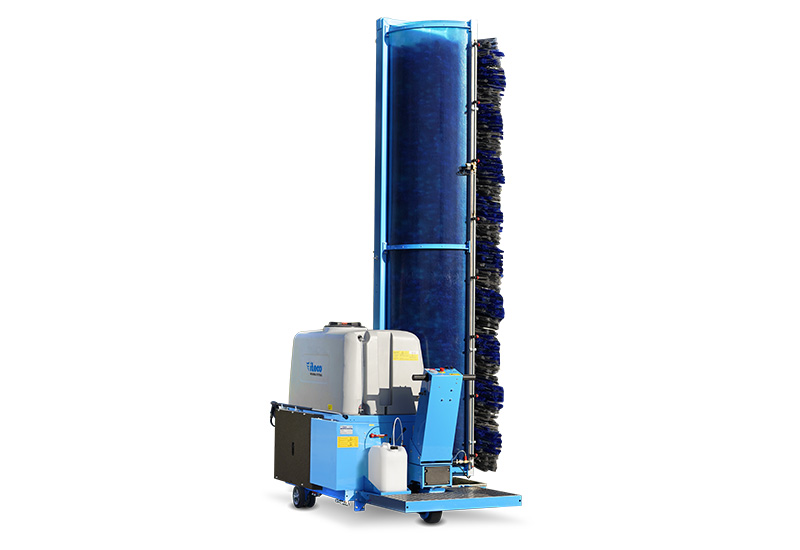

Iteco Washing Systems “Truck Wash” single brush washing systems, designed to offer a professional and practical washing service thanks to the standard equipment.

Washing system adaptable to any surface

The Truck Wash washing system consists of anti-scratch brushes and a tilting system, to clean even sloping surfaces of vehicles.

Controlled, safe and customizable driving system

Truck Wash single disc machines are safe and practical to drive.

The driving system consists of a tiller steering that favors controlled and fluid movement of the system.

The washing system control panel is located on the tiller head for excellent maneuverability and visual control of the vehicle washing operation.

The driving position for the operator can be customized in three alternatives:

On the ground

Standing on the platform

Seated on the platform

Discover the Truck Wash model that suits you best

The Truck Wash model is available in three configurations:

Truck Wash D 500

Basic model with tilting single brush and side chassis washing system. Diesel engine.

Truck Wash D 500 HP

Washing system with tilting single brush, side chassis, pressure washer and hose reel for deeper and more targeted cleaning. Diesel engine.

Basic model with tilting single brush and side chassis washing system. Battery powered electric motor.

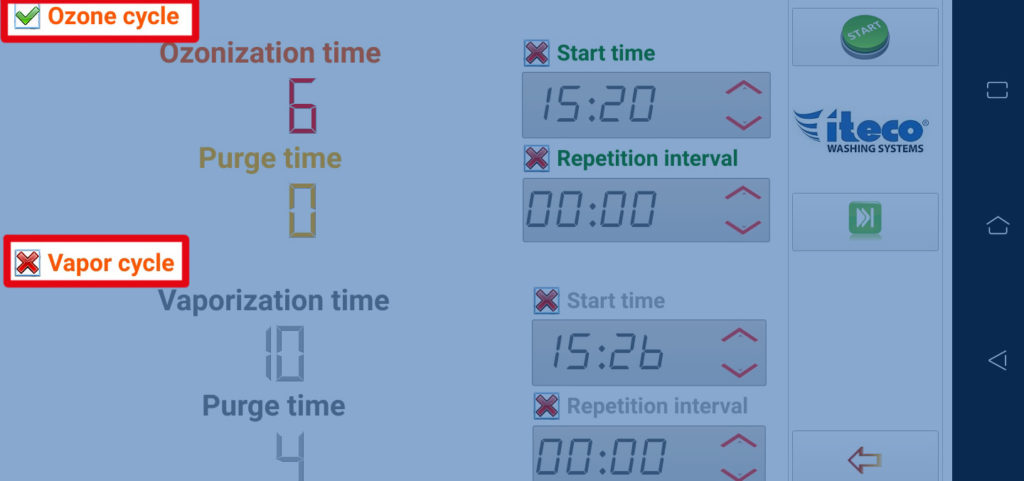

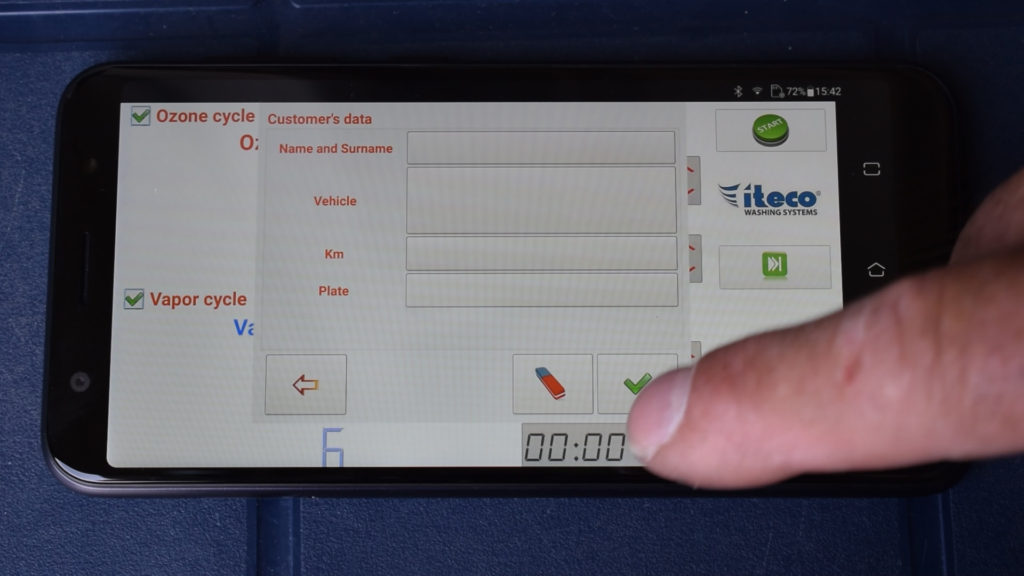

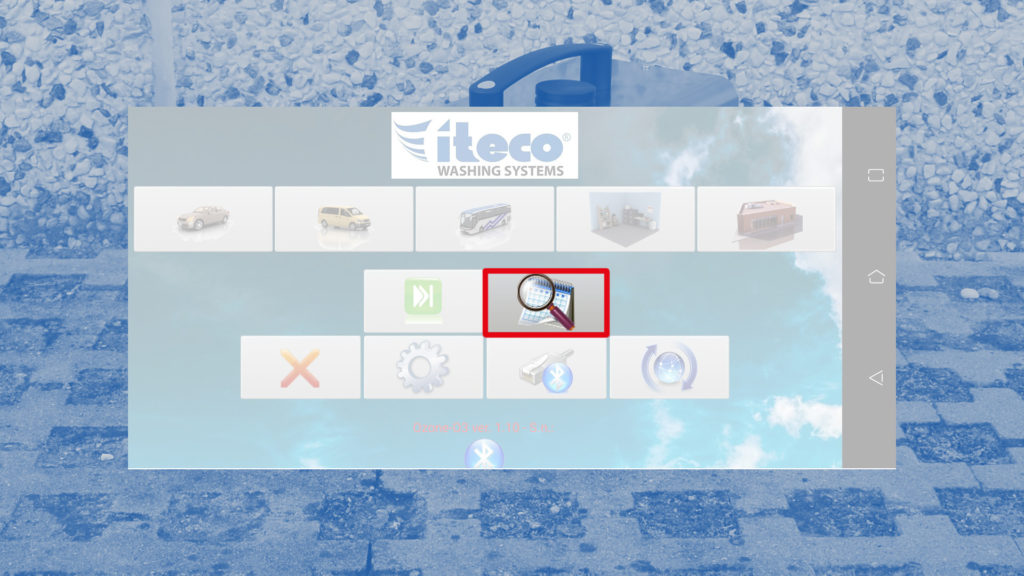

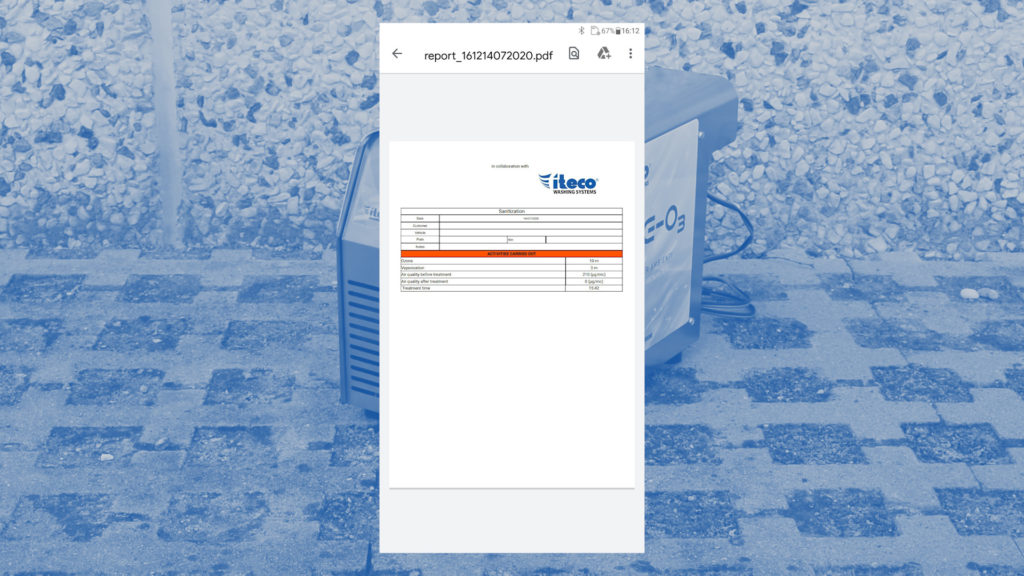

Per ulteriori dettagli e informazioni sulla stazione multi-igienizzante Ozone-O3: